Potassium Bicarbonate (KHCO₃): Comprehensive Guide to Industrial, Chemical, and Mining Applications

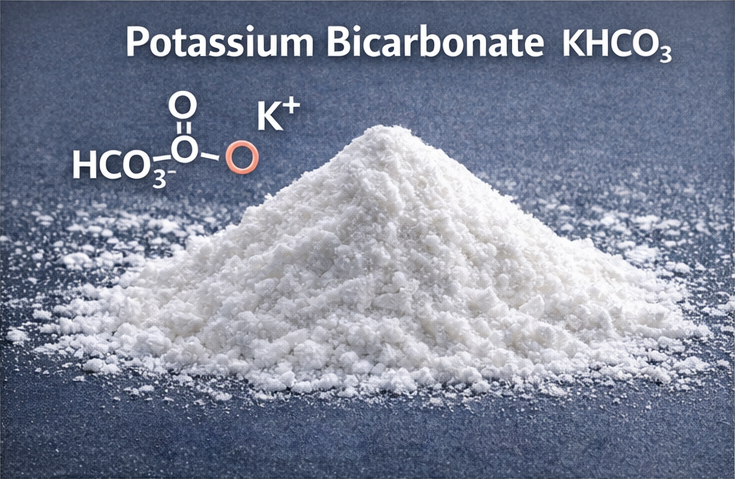

Potassium bicarbonate (chemical formula KHCO₃), also known as potassium hydrogen carbonate, is a white crystalline powder that is odorless and highly soluble in water. Its aqueous solution is mildly alkaline. As a single potassium salt, it consists of potassium ions (K⁺) and bicarbonate ions (HCO₃⁻), with a molecular weight of approximately 100.12 g/mol.

When heated, potassium bicarbonate decomposes to release carbon dioxide and water, converting into potassium carbonate. This thermal decomposition behavior gives it particular value in industrial and chemical manufacturing processes.

Under normal conditions, potassium bicarbonate is chemically stable, non-corrosive, and does not emit harmful volatile gases. These properties make it widely used in industrial sectors where safety, environmental friendliness, and mild alkalinity are required.

⚗️ Chemical Properties and Reaction Mechanism

From a chemical perspective, potassium bicarbonate is a weak alkaline salt with the following key characteristics:

Mild alkalinity: When dissolved in water, it produces a slightly alkaline solution, suitable for gentle pH adjustment.

Carbon dioxide release: CO₂ is released when heated or when reacting with acids, a property utilized in several chemical processes.

Buffering capacity: It stabilizes pH in acid–base systems, making chemical reactions more controllable and consistent.

Industrially, potassium bicarbonate is commonly produced by reacting potassium carbonate with carbon dioxide in an aqueous medium:

K₂CO₃ + CO₂ + H₂O → 2 KHCO₃

This reaction proceeds under normal temperature and pressure and remains one of the primary industrial production routes.

🏭 Core Applications in the Chemical Industry

⚖️ pH Buffering and Regulation

In chemical manufacturing, many reaction systems are highly sensitive to pH fluctuations. Even minor changes can affect product quality or yield. Due to its mild alkalinity and excellent solubility, potassium bicarbonate is widely used as a buffering agent to stabilize solution pH.

Typical applications include:

Chemical synthesis processes: Used to regulate the acidity or alkalinity of intermediates, preventing damage to catalysts or raw materials caused by strong acids or bases.

Analytical chemistry and laboratory use: Employed in acid–base titration, sample preparation, and controlled experimental systems to improve accuracy and reproducibility.

🧩 Chemical Intermediate Raw Material

Beyond its direct functionality, potassium bicarbonate also serves as an intermediate for producing other potassium-based chemicals:

Production of potassium carbonate (K₂CO₃): Through thermal decomposition, potassium bicarbonate converts into potassium carbonate, which is widely used in glass manufacturing, fertilizers, detergents, and soaps.

Synthesis of other potassium compounds: Such as potassium acetate and potassium arsenite, used as raw materials or intermediates in various industrial chemical processes.

These derivatives play a critical role in chemical supply chains, helping manufacturers optimize raw material costs and expand product portfolios.

💧 Water Treatment and Corrosion Control

Industrial wastewater and circulating water systems often suffer from acidification, which can damage equipment and disrupt downstream processes. Typical examples include mining effluent and chemical plant cooling water systems.

Potassium bicarbonate is applied in:

pH adjustment and buffering: Bringing water systems into a suitable pH range and preventing sudden pH fluctuations that may cause corrosion or biological imbalance.

Corrosion inhibition: It can form a mildly alkaline protective environment on metal surfaces, slowing corrosion rates. This feature has been increasingly adopted in petrochemical and industrial equipment maintenance.

Compared with strong alkalis such as sodium hydroxide (NaOH) or potassium hydroxide (KOH), potassium bicarbonate offers a safer and more environmentally friendly alternative, especially in applications where harmful ions must be minimized.

🔥 Fire Suppression and Industrial Safety

In fire safety and chemical protection fields, potassium bicarbonate is a key raw material for dry chemical fire extinguishing agents. The resulting powder is commonly known as “Purple-K”.

Its main advantages include:

High extinguishing efficiency: Particularly effective against Class B (flammable liquid) and Class C (electrical) fires.

Low corrosive residue: Unlike some halogen-based extinguishing agents, it does not significantly damage equipment.

Safe usage: Non-toxic and low irritation, suitable for industrial sites, processing plants, and equipment rooms.

As a result, potassium bicarbonate-based extinguishing agents are widely used in chemical plants, warehouses, oil & gas facilities, and other high-risk industrial environments.

⛏️ Potential Applications in the Mining Industry

Although potassium bicarbonate is less known in mining compared to its agricultural use, its industrial properties provide meaningful value in mining-related chemical processes.

⚙️ pH Adjustment for Acidic Slurries

Mining operations such as flotation and leaching rely heavily on precise pH control. Proper pH directly influences mineral separation efficiency and reagent selectivity.

Potassium bicarbonate can be added as a mild alkaline regulator to mining slurries, working alongside stronger acids or bases to buffer the system within a stable pH range. This helps to:

Improve selectivity during flotation of target minerals.

Reduce equipment corrosion and slurry instability caused by excessive use of strong alkalis.

♻️ Wastewater Treatment and Heavy Metal Precipitation

Tailings water and beneficiation wastewater often contain acidic substances and dissolved metal ions. Potassium bicarbonate can support wastewater treatment by:

Adjusting pH to promote precipitation of metal hydroxides.

Reacting with certain metal ions to form insoluble carbonates, improving filtration and recovery.

Supporting biological treatment systems by maintaining a stable micro-environment.

As mining operations increasingly adopt environmentally responsible practices, this non-toxic and eco-friendly buffering agent becomes more attractive.

📦 Storage, Packaging, and Safe Handling

For export and industrial storage, proper handling of potassium bicarbonate is essential:

Storage conditions: Keep in a dry, well-ventilated, and shaded warehouse to prevent moisture absorption and caking.

Packaging: Industrial-grade material is typically packed in plastic-lined woven bags, commonly 25 kg per bag, for easy transportation and storage.

Safety precautions: Avoid dust generation during handling. Use basic personal protective equipment such as dust masks, gloves, and goggles. In case of spillage, collect and dispose of according to local regulations.

Compatibility: Avoid prolonged contact with strong acids or strong oxidizing agents to prevent decomposition or undesirable reactions.

📈 Market Trends and Future Outlook

As industrial sectors increasingly emphasize green chemistry, environmental protection, and safe production, potassium bicarbonate shows strong growth potential in several areas:

Replacement of corrosive fire extinguishing agents in industrial safety regulations.

Development of advanced buffering materials for fine chemicals and pharmaceuticals.

Expanded applications in water treatment systems, including wastewater and industrial circulation systems.

New uses driven by environmentally friendly mining technologies, particularly as a mild pH regulator and buffer.

The growing demand for low-toxicity, mildly alkaline, and environmentally compatible chemicals provides significant market opportunities for multifunctional salts such as potassium bicarbonate.

🧾 Conclusion

As a chemical material with a long history yet evolving applications, potassium bicarbonate (KHCO₃) extends far beyond food and agricultural uses. Its buffering performance, safety profile, and versatility in fire suppression, water treatment, and mining-related chemical processes make it a valuable product for chemical exporters and industrial users alike.

A deeper understanding of its multi-layered industrial applications helps suppliers better serve international markets, develop customized solutions, and enhance product value in an increasingly sustainability-driven global chemical industry.You can place an order or ask any questions, please feel free to contact at feronia@wit-stone.com | +86-15655559799