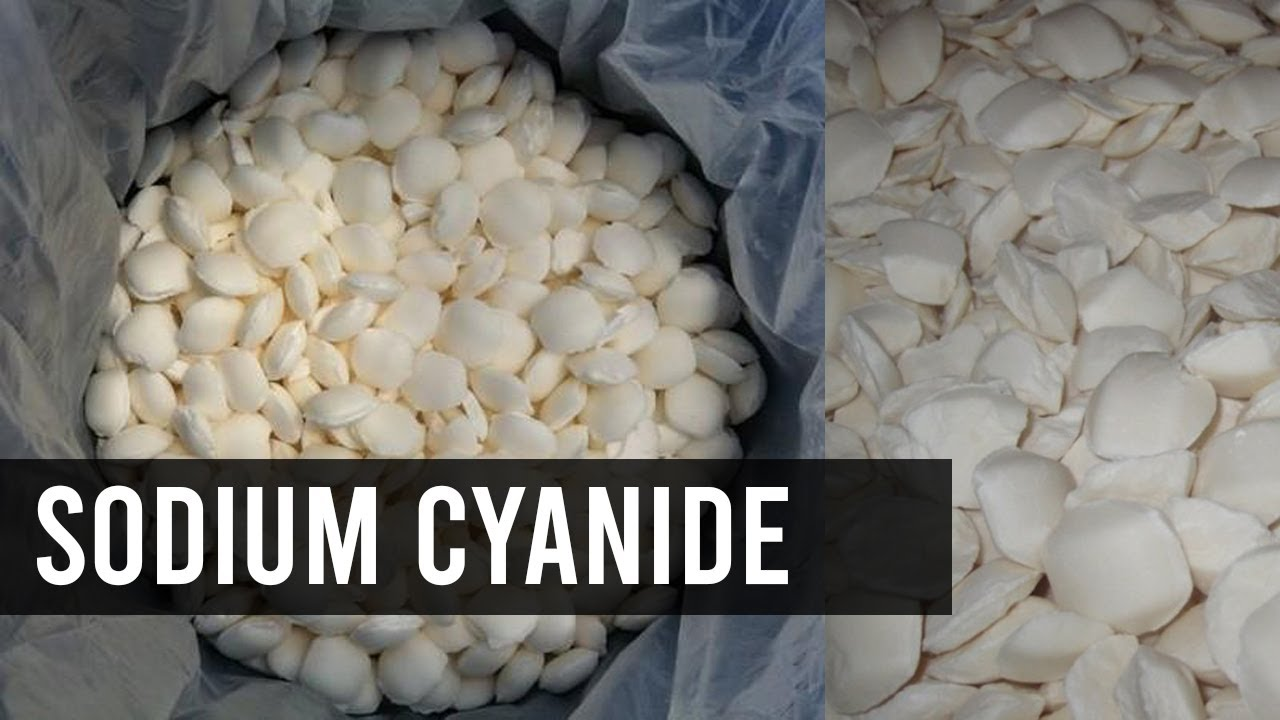

Important Chemical Product: Overview of Sodium Cyanide

Sodium cyanide (NaCN), with a molecular weight of approximately 49, typically appears as white flakes or crystalline granules. It is highly hygroscopic and may have a faint bitter almond odor (though some individuals cannot detect it due to genetic differences). It is strongly alkaline, highly soluble in water (approximately 63.7 g/100 mL at 25°C), and also dissolves in ammonia and alcohols.

Sodium cyanide readily hydrolyzes to form the highly toxic hydrogen cyanide (HCN), especially when in contact with acids. Therefore, strict pH control and proper ventilation are required during production and use.

Catalog

🏭 Production Methods & Chemical Properties

🔧 Production Methods

Reaction of hydrogen cyanide with sodium hydroxide:

HCN + NaOH → NaCN + H₂OAlternatively, it can be produced by heating sodium amide (NaNH₂) with carbon (Castner-Kellner process).

⚙️ Physical and Chemical Properties

Melting point: 563.7 °C, boiling point: 1496 °C, density: 1.5955 g/cm³

Highly toxic, with an oral LD₅₀ of 4–15 mg/kg in animal models; occupational exposure limit: 5 mg/m³ (TWA)

Easily hydrolyzes to produce HCN gas, posing serious risks to both humans and the environment.

🌐 Broad Applications of Sodium Cyanide

⚗️ 1. Intermediate in Organic Synthesis

Sodium cyanide is a key reagent for producing chemical intermediates such as nitriles and cyanate esters. It is also used in the pharmaceutical industry to synthesize intermediates for β-lactam antibiotics, vitamin B₆, folic acid, diethyl malonate, and sodium cyanoacetate.

🧫 2. Synthetic Materials and Polymer Industry

In the plastics and rubber industries, NaCN is used in the synthesis of monomers like acrylonitrile and methyl methacrylate (PMMA). It also serves as a vulcanization aid for nitrile rubber and as a precursor for engineering plastics and composite materials.

🎨 3. Dyes and Textile Industry

Sodium cyanide is used in the synthesis of various dyes including Yellow 139, Yellow 150, indigo, and optical brighteners. These are widely applied in textiles, plastics, and paper. It also acts as a mordant and is used in liquid-phase carburizing and nitriding of fibers.

🌾 4. Fine Chemicals and Additives

NaCN is a raw material for several pesticides, such as glyphosate, chlorantraniliprole, and azoxystrobin. It also plays a role in manufacturing fragrances, UV absorbers, and chelating agents.

🧪 5. Analytical Reagents and Masking Agents

In analytical chemistry, sodium cyanide is used as a masking agent during the electroplating and refining processes, particularly for stabilizing ions such as chromium and zinc.

🔩 Applications in Metal Processing

Sodium cyanide is extensively used in electroplating and metal surface heat treatment.

⚡ Electroplating

In electroplating, NaCN forms complexes with metals like copper, zinc, silver, and cadmium. It enhances the conductivity of the electrolyte, controls impurities, and promotes uniform metal deposition. It is a key component in plating solutions for copper, silver, cadmium, and zinc.

🔥 Surface Heat Treatment

NaCN is also used in case hardening processes, where it helps form carbon-nitrogen compound layers on metal surfaces, thereby increasing their hardness and wear resistance.

⛏️ Applications in Mining Industry

Sodium cyanide’s most critical use in mining is for gold and silver extraction through leaching.

💧 Leaching Process

Known as cyanidation, this process became dominant in the 1970s. Crushed ores are mixed with a sodium cyanide solution (typically 0.025% or ~250 ppm) to dissolve Au and Ag into soluble complexes. For low-grade ores, heap leaching is employed at a NaCN-to-ore ratio of roughly 1:500–1000.

♻️ Recovery and Refining

Gold and silver are recovered from the pregnant solution using zinc powder precipitation or activated carbon adsorption.

🌍 Global Use

Around 30% of global gold is produced via cyanidation. Mining accounts for about 15% of all industrial cyanide usage. Despite its toxicity, the method remains standard due to its high efficiency, cost-effectiveness, and mature environmental management technologies.

🛡️ Safety and Protection Measures

As a highly toxic substance, sodium cyanide poses serious risks to human health, the environment, and public safety. Strict safety protocols are essential.

☣️ 1. Routes of Exposure

Inhalation: Dust, mist, or HCN gas can lead to poisoning.

Ingestion: Contaminated hands or accidental ingestion during meals can cause acute poisoning.

Skin/Eye Contact: Cyanide ions can be absorbed through skin, causing systemic toxicity.

🧬 2. Acute and Chronic Toxicity

Acute poisoning: Symptoms include dizziness, nausea, seizures, respiratory or cardiac failure, and death within minutes.

Chronic exposure: May result in optic nerve damage, nervous system disorders, and other health issues.

🦺 3. PPE and Engineering Controls

Recommended safety measures based on electroplating and mining practices include:

Personal protection: Chemical-resistant gloves (nitrile or butyl rubber), protective clothing, boots, goggles/face shields, and full-face respirators with HCN cartridges.

Ventilation: Local exhaust ventilation during mixing; fixed and portable HCN monitors at mining sites.

Facility management: Storage must be at least 50 meters from acids, in sealed, labeled, dust-proof containers with access controls.

📦 4. Storage and Handling

Sodium cyanide should be packaged in sealed drums, clearly labeled as “Highly Toxic—Sodium Cyanide”, conforming to UN 1689 standards. Transported as Class 6.1 toxic substance. A register-based issuing system should be enforced, with operations limited to authorized personnel.

🚨 5. Emergency Response

Spill management: Neutralize with hypochlorite or thiosulfate; isolate and contain spills to prevent environmental contamination.

First aid: Remove contaminated clothing, rinse skin/eyes for at least 15 minutes; move inhalation victims to fresh air and provide respiratory support; seek immediate medical help.

Fire response: Avoid acid mixtures, as high temperatures can release HCN. Use appropriate extinguishing agents and full protective gear.

📘 6. Compliance and Industry Standards

Operations must follow International Cyanide Management Code (ICMC) covering production, transportation, usage, wastewater treatment, tailings management, and staff training.

✅ Conclusion

Sodium cyanide remains an irreplaceable chemical in metal treatment and mining operations due to its excellent complexing capabilities and high extraction efficiency for gold and silver. However, its extreme toxicity demands rigorous handling procedures, personnel protection, engineering controls, and environmental responsibility.

With strict adherence to safety and compliance, sodium cyanide will continue to deliver vital value in electroplating, mining, and other industrial sectors, supporting efficient development across the chemical supply chain.

You can place an order or ask any questions, please feel free to contact at feronia@wit-stone.com | +86-15655559799