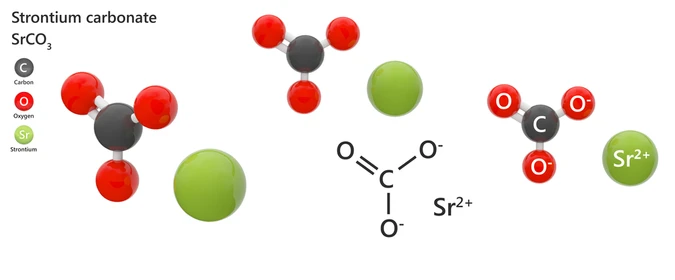

Comprehensive Analysis of Strontium Carbonate: Properties, Applications, and Environmental Benefits

Strontium Carbonate (chemical formula: SrCO₃) is an important inorganic compound widely used in electronics, ceramics, metallurgy, displays, and new energy fields due to its unique physical and chemical properties. Recently, with the rising demand for environmentally friendly materials, strontium carbonate’s value as a green alternative has garnered increased attention. This article provides a comprehensive analysis of its properties, main applications, and environmental advantages.

1. Basic Properties of Strontium Carbonate

Strontium carbonate is a white or grayish powder with stable chemical properties, soluble in acids but insoluble in water. When heated, it decomposes to release carbon dioxide and produce strontium oxide. The following table outlines its main physical and chemical properties:

| Property | Value |

|---|---|

| Chemical Formula | SrCO₃ |

| Molecular Weight | 147.63 g/mol |

| Density | 3.5 g/cm³ |

| Melting Point | 1100°C (decomposes) |

| Water Solubility | Insoluble |

| Solubility | Soluble in acids |

2. Major Applications of Strontium Carbonate

Strontium carbonate has versatile applications across multiple industries, playing an irreplaceable role in each due to its performance characteristics.

1. Displays and Phosphor Materials

Strontium carbonate serves as a precursor in phosphors and is crucial in display and lighting materials, especially for high-brightness, wide-color-gamut displays. With the development of OLED and quantum dot displays, demand for strontium carbonate in this sector is rapidly increasing.

- Phosphor Market Demand: By 2025, the phosphor market is projected to reach $350 million, with strontium carbonate holding a significant role.

2. Electronic Ceramics

In electronic ceramics, strontium carbonate is a key raw material in the production of strontium titanate and barium titanate, which are used in multilayer ceramic capacitors (MLCC) and piezoelectric ceramics. Compared to traditional lead-based ceramics, strontium carbonate-based ceramics are more environmentally friendly and exhibit superior electrical performance in high-frequency electronic devices.

- Global Demand for Electronic Ceramics: The market for electronic ceramics reached $11 billion in 2023, with the share of strontium carbonate-based ceramics steadily rising.

3. Metallurgical Industry

Strontium carbonate plays an essential role in metallurgy, particularly in aluminum alloys and rare earth metals, where it serves as a refining and modifying agent to improve metal microstructure, toughness, and mechanical properties.

1) Applications in Aluminum Alloy Production

In aluminum alloy production, strontium carbonate improves the alloy’s performance, especially for high-strength aluminum alloys. Strontium-modified aluminum alloys exhibit enhanced wear resistance and ductility, making them ideal for high-strength, lightweight applications in aerospace, automotive, and electronic enclosures.

- Mechanism: Strontium carbonate acts as a grain refiner, influencing grain nucleation and growth during solidification, resulting in a more uniform metal grain structure. This uniformity enhances strength, ductility, and toughness.

- Impact: Research shows that strontium-carbonate-modified aluminum alloys can achieve 20-30% finer grain structures, with overall tensile strength improved by approximately 10% and ductility by 15%.

- Environmental Significance: Strontium carbonate replaces some traditional alloy modifiers, reducing the need for toxic or costly metals, aligning with green manufacturing standards.

2) Applications in Rare Earth Metal Refining

In rare earth metal refining, strontium carbonate acts as a refining agent to effectively remove impurities. For instance, in refining rare earth oxides, strontium carbonate captures impurities (such as sulfur and phosphorus), resulting in higher-purity rare earth metals suitable for electronic, magnetic, and new energy device manufacturing.

- Mechanism: During refining, strontium carbonate decomposes and reacts with impurities, forming easily separable compounds, significantly improving the purity of rare earth materials.

- Example: In the production of neodymium-iron-boron magnetic materials, strontium carbonate enhances the purity of rare earth metals, resulting in more stable, durable magnetic materials.

| Application Field | Role | Specific Impact | Market Value |

|---|---|---|---|

| Aluminum Alloy | Grain Refiner | Improves strength, wear resistance, ductility; suits lightweight, high-strength applications | Aerospace, Automotive, Electronics |

| Rare Earth Refining | Refining Agent | Enhances rare earth metal purity, improves magnetic material performance, suitable for electronics and new energy devices | Rare Earth Market |

4. New Energy Materials

With the growing global demand for new energy, strontium carbonate is increasingly valued in the energy storage battery and other new energy materials fields. It enhances battery stability and longevity, actively supporting innovation in efficient energy storage systems.

1) Additive Role in Lithium Batteries

Strontium carbonate’s chemical stability makes it an ideal additive for lithium-ion and novel energy storage batteries. It stabilizes battery materials, reducing degradation during cycling, thus extending battery life.

- Mechanism: Strontium carbonate forms a protective film on active materials, inhibiting excessive oxidation and preventing structural damage due to temperature rises or repeated charging and discharging.

- Impact: Experimental data indicate that adding strontium carbonate to lithium batteries can extend battery life by approximately 10-15%, especially in high-frequency discharge applications.

2) Modification in Solid-State Battery Materials

Solid-state batteries, known for high safety and energy density, are the mainstream future direction in battery technology. Strontium carbonate, as a modifier in solid electrolyte materials, optimizes ionic conductivity, enhancing battery charging and discharging efficiency.

- Mechanism: In solid-state batteries, strontium carbonate improves electrolyte interface structure, reduces resistance, and speeds up lithium-ion transfer.

- Impact: Studies show that solid-state batteries incorporating strontium carbonate exhibit over 20% improved ion conductivity, with better cycle stability, suitable for electric vehicles and energy storage systems.

3) Prospects in Sodium-Ion Batteries

As a next-generation energy storage material, sodium-ion batteries are increasingly valued for their abundant resources and cost advantages. Strontium carbonate can improve the structural stability and lifespan of sodium-ion batteries, optimizing discharge characteristics.

- Environmental and Cost Advantages: Compared to lithium batteries, sodium-ion batteries are cheaper to produce and have more abundant resources. The addition of strontium carbonate enhances their competitiveness, meeting the market’s low-cost, high-performance energy storage needs.

| New Energy Application | Role | Specific Impact | Environmental Benefit |

|---|---|---|---|

| Lithium Batteries | Material Stabilizer | Extends battery life, reduces cycle degradation; ideal for high-frequency charging/discharging | Reduces material waste, extends battery life |

| Solid-State Batteries | Ionic Conductivity Modifier | Improves charging efficiency, cycle stability; suits EVs and storage devices | Lowers charging energy consumption, extends usage period |

| Sodium-Ion Batteries | Structural Stabilizer | Enhances stability and lifespan, boosts sodium-ion battery competitiveness | Lowers production costs, abundant resources |

3. Environmental Benefits of Strontium Carbonate

As global environmental regulations tighten, strontium carbonate is gradually replacing materials containing heavy metals in certain fields. Its environmental advantages include:

- Lead-Free Replacement Material: Strontium carbonate is increasingly replacing lead-based materials in electronic ceramics, reducing the use of harmful metals and meeting international environmental standards.

- Low Toxicity: As an inorganic compound, strontium carbonate has low toxicity, posing minimal risk to humans and the environment.

- Energy Efficiency: Strontium carbonate production is relatively simple, with lower energy consumption, contributing to low-carbon production.

| Environmental Advantage | Specific Impact |

|---|---|

| Lead-Free Replacement | Replaces lead titanate, reduces heavy metal pollution |

| Low Toxicity | High safety, meets environmental standards |

| Low Energy Consumption | Low-carbon production |

4. Market Trends and Future Outlook

Over the next five years, demand for strontium carbonate in electronic ceramics, phosphor materials, and new energy sectors is expected to grow steadily, with a projected compound annual growth rate of 4.5%. Particularly in metal and battery material modification, strontium carbonate not only enhances product performance and stability but also aligns with environmental and sustainability goals. With the rapid development of green industries, strontium carbonate will continue to play a key role across applications, supporting the industry’s green transition with its multifunctionality and environmental benefits.

You can place an order or ask any questions, please feel free to contact at feronia@wit-stone.com | +86-15655559799

Resource Link: More About Strontium Carbonate